- #Hemera ender 3 v2 pdf#

- #Hemera ender 3 v2 install#

- #Hemera ender 3 v2 update#

- #Hemera ender 3 v2 plus#

M906 X800 Y800 Z800 E800 I50 set motor currents (mA) and motor idle factor in per cent Thermistor / Heaters I found that setting it to a lower current of E800 was satisfactory. In order to provide the Hemera motor with the correct amount of current, so as to have it’s ideal torque level, and not over heat, it is required to make some adjustments to the VREF on your stepper drivers.Į3D recommends setting the motor current to around E980 (mA). The standard Hemera motor has a rated motor current of 1.33A. I found that I needed to tweak that 409 value to E392.70 for more precise extrusion M92 X80.00 Y80.00 Z800.00 E392.70 set steps per mm Motor Current

#Hemera ender 3 v2 pdf#

The wiring detailed in my PDF ensures all the motors turn in the same direction.

#Hemera ender 3 v2 update#

Chris does a great job of breaking down all of the configuration file changes.Īfter wiring the Hemera you will need to update some parameters in the Duet’s config.g file per the E3D reprap directions. Recently a youtuber “Chris’ Basement” put out a video of installing the Hemera on an Ender 3 with a Duet mainboard. I recommend adding quick disconnects to both Fans to make them easier to change out in the event of a failure. I will link to a PDF to show the wiring and connector orientation used. I used Cat6 Ethernet cable for the Extruder and X-axis. I installed both the Hemera and the Duet 2 at the same time as updating the wiring. Make sure you get the right fan and Hemera (24VDC).

#Hemera ender 3 v2 install#

During this install keep in mind that the Ender 5 Pro power supply is 24VDC and NOT 12VDC.

#Hemera ender 3 v2 plus#

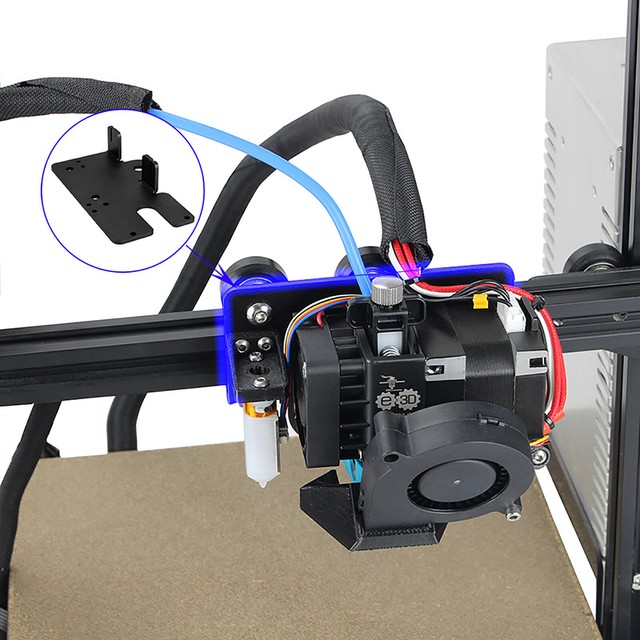

For some guidance I recommend watching this video from 3D Printing Canada using Although the video shows an Ender 5 PLUS model which is not an exact match for the Ender 5 Pro it was very useful to help me understand the entire process. Now that you have printed your mount you can safely start removing the stock direct drive motor from the frame of the Ender 5. Hemera with Metal BL Touch Mount Removing the current hot end and drive system

Ideally you print in something durable like PETG or ABS.

Hemera on my Ender 5 with BL Touch Hemera Installīefore you start taking your printer apart you need to print a new mount for the Hemera.

The stock Bowden setup can have speed advantages because you have less weight on the moving parts and thus less inertia to overcome when the extruder needs to rapidly change directions.

0 kommentar(er)

0 kommentar(er)